-

Design functional aquaculture farms;

Design aquaculture farm is It is the first object of activity for OLOOSON Caviar & Fish Factory. Which is dedicated to design strong recirculating aquaculture system.

Today the importation of fish at EU level is over 70%. Extensive farming systems (ponds, lakes) and not provide operability required to start up a production cycle at any time of year.

They are dependent on the ambient temperature cycles and seasons. Fish production per hectare not exceeding 200 kg in the system without feeding and intensive feeding up to 2,000 kg.

But even with the highest yields per hectare that are harvested in autumn, when all farmers do the same, lowers the sales price, due to the abundance of fishery products in the same time.

The rest of the year and therefore offer no department store chains that actually imported fish products come mainly from recirculating systems of others. And this is why the vast majority of fish farmers have difficulties in entering the Romanian fish products in retail chains.

-

Design Aquaculture Farm small, medium and large capacity in recirculating system.

Design aquaculture farm starting with capacities of 2 or 3 tons, named PFA (authorized person) farms, through 50 tons category, SRL farms (limited liability company) and farms or reaching over 150 tonnes called farms SA (stock company), the principles realization aquaculture farm remain the same. But the value of the investment and that the money obtained from the European Fondurilr are “expensive” limit us to have an approach of maximum area like SRL.

-

Design of wells and pumping systems.

-

Design of reproductive aquaculture units: carp, perch, trout, sturgeon, tilapia, clarias.

-

Design of mechanical filters for recirculating system.

-

Design of mechanical filters at the inlet/discharge water from the farm.

-

Design of filtering bio-vegetal pools (ponds, lakes).

-

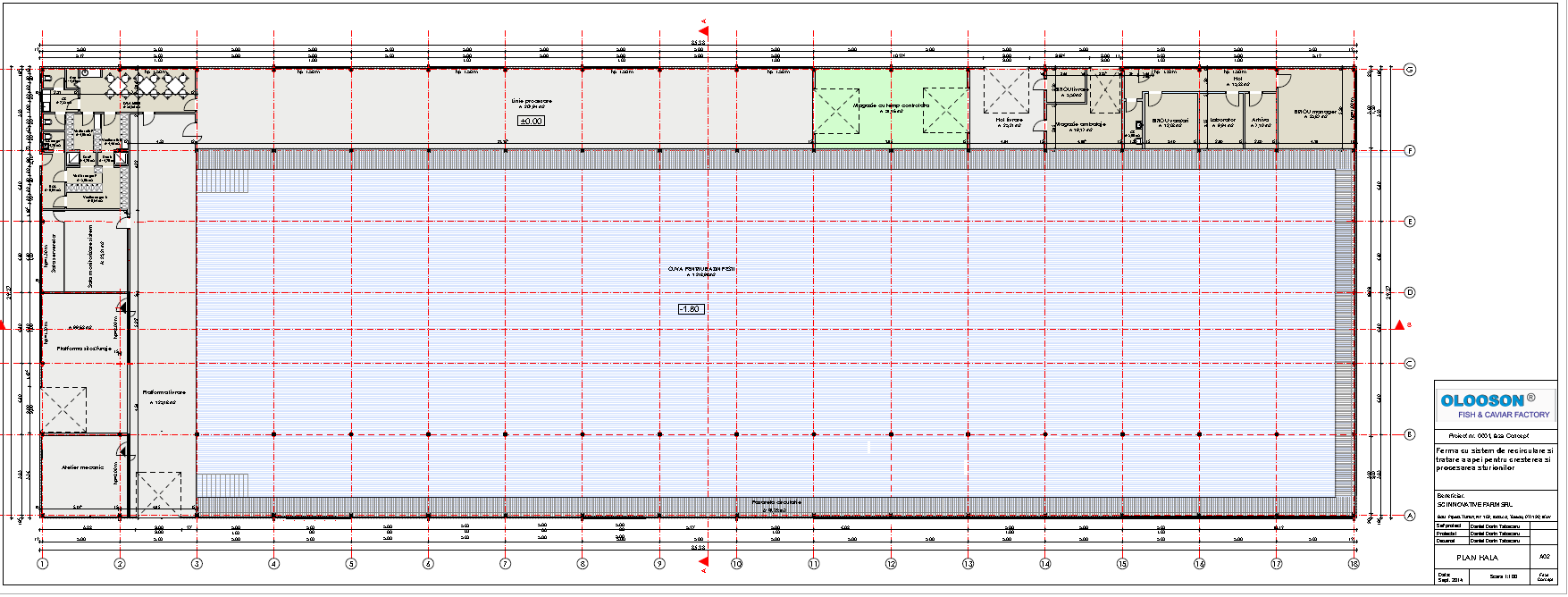

Design hosting hall of aquaculture farm.

-

The Design of infrastructure systems (fence, lighting, access).